Case Study – Real time Embedment (Embed) selection in Facade Engineering

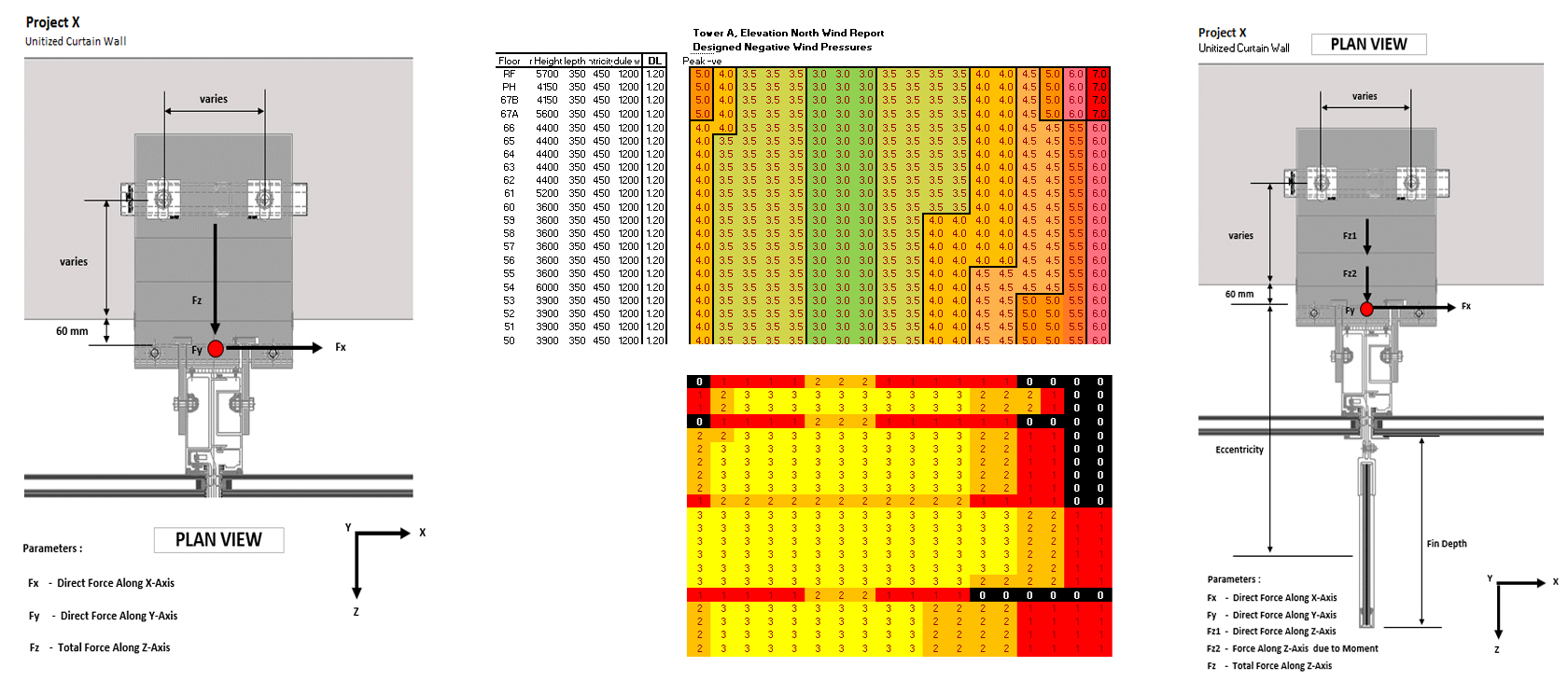

Script Monkey has implemented real time embed selection in Facade Engineering by using a heat map for wind loads, then selecting worst case loads from Fx, Fy, Fz and Moments.

During detailed façade engineering, embeds are selected by an FSE (façade structural engineer) based on wind loads and panel eccentricities. This process usually takes several weeks for a large building and is complicated by particular vendors being preferred by contractors or clients, limiting selections. Bespoke curtain wall design and the positioning of embeds in relation to slab edges influence loads and all loads must be checked.

At the early stage of façade design, many jobs go across the desk of the FSE and there can be significant bottlenecks due to other FSE priorities which is why this process can take weeks.

By taking simplified formulas for Fx, Fy, Fz and Moment loads from the FSE initially and coordinating with the Main cont4ractor for embed position with respect to edge of slab, initial selection can be done for all locations using automation, which only later need be checked statistically by an FSE, saving time at a critical time when FSEs are busy with sizing profiles and working on large scale, long lead structural items like steel inserts and custom cast-ins which cannot be bought from embed vendors.

The technique we employed was to create a wind load ‘heat map’ representing the façade and then calculate the forces at each location based on the positive and negative wind loads with the worst case of the four primary loads then driving selection for that panel location. Finally, the cases were reconciled to have a single embed size at each floor elevation as it is difficult to manage QA/QC effectively if you have metals to set in concrete which have similar appearance and yet have different structural performance. Better to take the worst case and oversize the lesser cases to ensure that no mistakes in placement lead to structural issues.

The role of the structural engineer becomes one of initial guidance to provide correct formulas for loadings based on eccentricities and to then check worst cases statistically after sizing has been done.

The huge advantage of such a system is that embedments can be long lead items, so saving 3-4 weeks at the front end of design ensures that every embedment is ready when the formwork goes in and before the concrete is ready to be poured.